Junction Temperature Estimation

Junction temperature (Tj) estimation uses temperature sensitive electrical parameters (TSEPs) from the IGBT and diode, measured on the gate drive, to estimate the on-chip junction temperature. It is not just a calculation of device temperature (Tj “simulation”, i.e. loss look-up tables plus a thermal model), and not just a measurement of the module temperature sensor, e.g. NTC thermistor.

Amantys has developed a novel algorithm for auto-calibration of the temperature estimation, giving wide tolerance to variations between IGBT module batches. By extracting device and module parameters during converter operation, it tracks parameter variation and enables condition monitoring.

Tj Estimation outperforms traditional temperature sensors – e.g. baseplate or in-module NTC sensors – giving much greater accuracy (< 5°C error). It also avoids time-consuming thermal model extraction required for online Tj “simulation”, which is also subject to large errors during degradation.

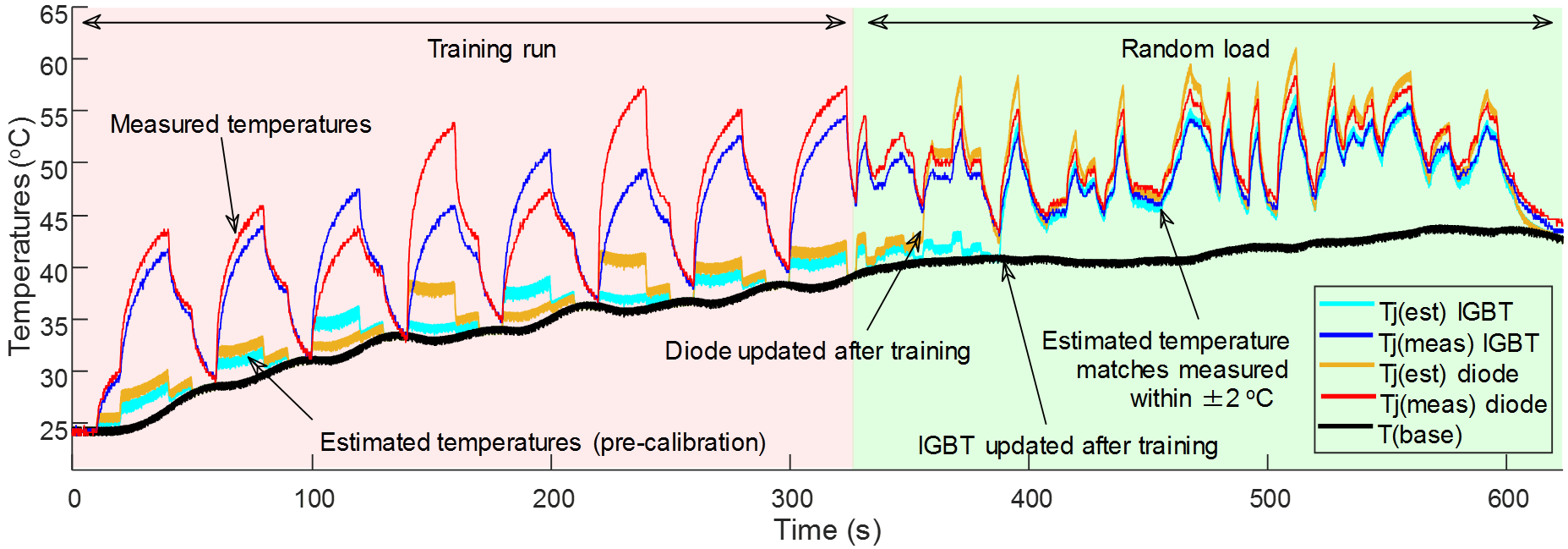

The following figure shows a comparison of estimated junction temperatures and measured junction temperatures, including a training run and a random mission profile. (Note that the calibration does not require knowledge of the measured junction temperature.)

Junction temperature estimation enables the following features in power converters:

- IGBT/diode over-temperature detection

- Improved validation of inverter stack design during development and type testing

- Dynamic rating control: intelligent over-rate/de-rate

- Optimised parallel inverter stack current sharing

- Condition monitoring: detection of wear-out and abnormal operation, giving predictive maintenance.

Resulting benefits to the converter manufacturer are the ability to optimize performance (rating or efficiency) for a given cost, e.g. through reduction of margins, and to the end user (operator) the early detection of abnormal operation and potentially reduced operating costs.